Techniques for glare removal in machine vision

How to solve this problem? There are several methods depending on the morphology of the object and the technical characteristics of the project, available space, maximum cycle time, need to see colors, etc...

Changing the relative angle between camera and illumination

The first option is to change the relative angle between the camera and the illumination, so that the light beams incident on the object do not bounce back to the camera directly. However, the homogeneity of the light is still poor and the total elimination of glare on highly reflective or cylindrical surfaces is not achieved.

Use of polarizing filters

Whenever a beam of light strikes a material, especially if it is metallic with a high degree of reflection, the light beams are returned at the same angle of incidence, but in the opposite direction, which causes a mirror effect and associated unwanted glare. In order to eliminate them, polarizing filters are used which are barriers that eliminate this excess amount of light, which on the contrary, greatly reduce the amount of light received by the sensor, increasing the cycle time, additionally if the application wastes colors it can cause that they do not look the same as in reality.

Use of fully diffuse illumination

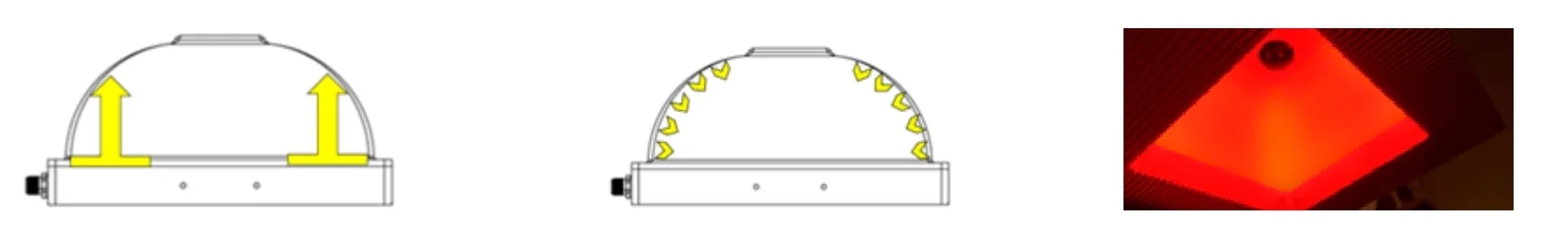

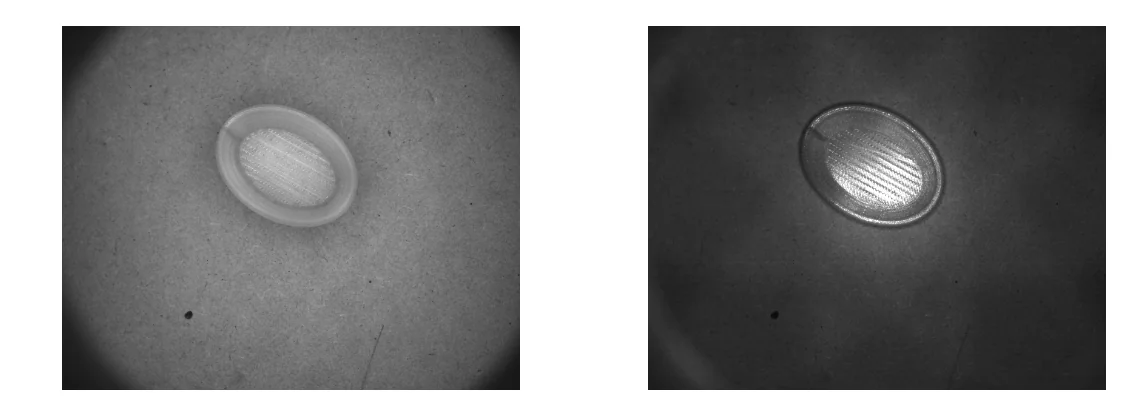

In this type of lighting, the light beams generated bounce off the walls of the luminaire itself, causing the light to hit the object equally from all directions, homogenizing the light in the image and reducing the associated brightness, it is also called cloudy day lighting. To achieve this, the light is generated from the bottom up, always focused on the walls of the dome and not on the object directly, the light beams bounce off the wall hitting the object from multiple directions instead of a single dominant direction.

With this type of luminaire, the cycle time is not seriously affected and the colors of the target part are respected.

Conclusions

Knowing the multiple advantages of the DOMO type lighting, Lumher has designed and manufactured a DOMO type product to facilitate the work of the vision engineers, offering a robust product (IP65) with several types of operation (continuous, pulsed and stroboscopic) and several wavelengths (white, red, infrared and ultraviolet) and with 36 months of guarantee of operation.

If you are interested in this product or want to know more about other lighting solutions that we have for machine vision do not hesitate to contact us!

Publicaciones destacadas